Double Compression Pipe Fittings

Advantages of Double Compression Pipe Fittings

[Reliable and Safe Connection]

The double compression pipe fittings has high connection strength and is anti-vibration, which can lock the connection part and avoid the possible looseness of the “movable joint”, such as looseness caused by reasons including vibration of water hammer, house vibration, pipeline resonance etc.

[Convenient and Fast Construction]

It is very convenient to install the double compression pipe fittings on site, and the installation time is only 1/3 of the time of welding and casting work, which greatly shortens the construction period and reduces the cost.

[Superior Economic Performance]

The stainless-steel pipe has strong corrosion resistance, and can keep its smoothness inside after long-term use, therefore it doesn’t need maintenance basically. Besides, its energy consumption is rather low. Hence, stainless-steel pipe is very cost-effective.

[Suitable for Embedded Installation]

Double compression pipe fittings are suitable for embedded installation, which greatly reduces the possibility of water leakage in hidden part of the pipe and meets the requirements of CECS 153:2003 Technical Specification for Thin-walled Stainless-steel Pipes for Building Water Supply (pipes with thread are not suitable for embedded installation).

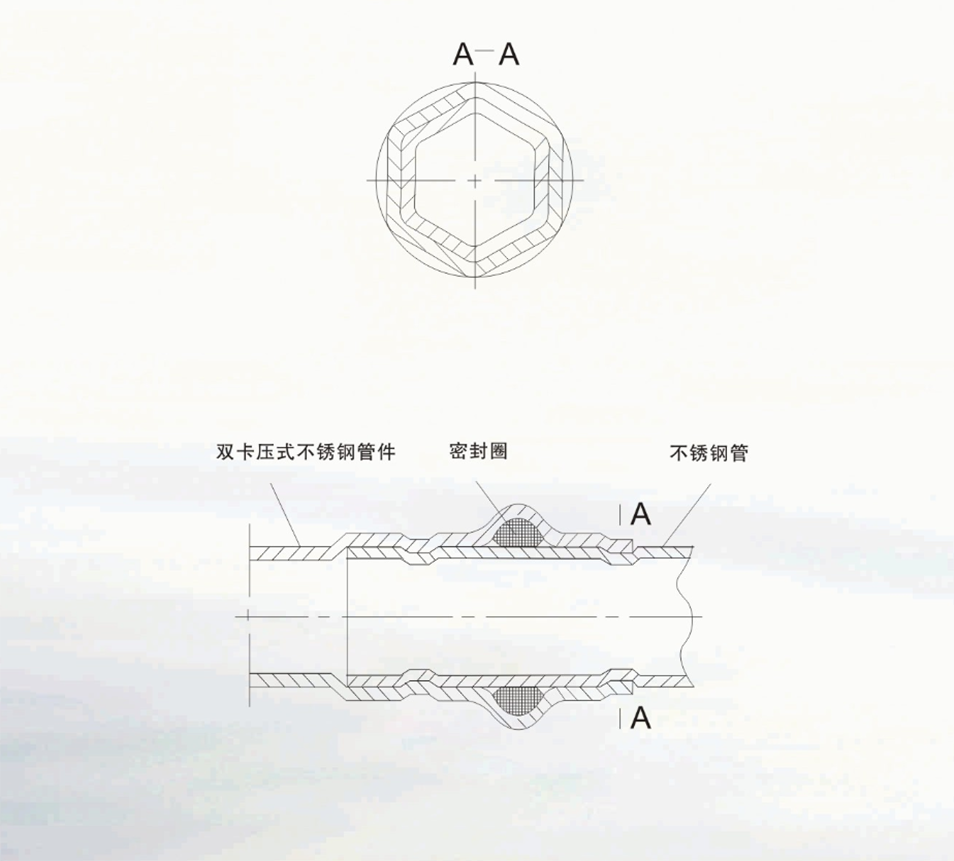

Principle of Double Compression Pipes

By taking full advantage of the rigidity of metal materials, the joint between the pipe and fittings and both ends of the pipes are connected with calipers to realize surface fixation, and are pressed into two hexagons and locked tightly, thus greatly improving its anti-drawing ability and anti-rotation ability. The double compression pipes adopt the advanced compression ratio principle of type 0 sealing ring, After the type 0 sealing ring is compressed in the U-shaped groove, it gives full play to its long-acting elasticity, thus achieving the purpose of permanent sealing. In addition, because of the advantages of the connector, double compression pipes can effectively prevent the risk of leakage when the pipe is not inserted to the end during construction.

1. Principle of anti-pull: small at both ends and big in the middle, anti-pull strength >3.0MPa

2. Principle of anti-leakage: prevent leakage by seepage rather than stoppage

3. Principle of anti-rotation: pressed into hexagons to prevent the leakage because of rotation in use

Key Process Treatment of Stainless-steel Pipe Fittings

◆ Anti-corrosion of stainless steel: The quality of stainless steel pipe depends largely on the process at the time of welding and that after welding.

◆ Gas shielded welding, temper color removal, solid solution and passivation treatment are the key processes to prevent weld corrosion:

1. The effect of gas shield

Under gas protection, the chromium and nickel on the surface of stainless steel will not be damaged during welding, and the original characteristics and corrosion resistance of stainless steel are retained.

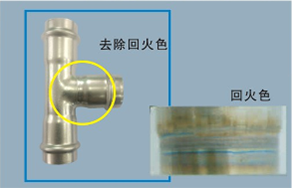

2. Remove temper color

The temper color is actually a mixture of chromium oxide iron oxide. The existence of temper color destroyed the passivation film of stainless steel, resulting in point corrosion and intergranular corrosion and so on.

3. The effect of solid solution

Solid solution is also one of the key measures to prevent corrosion of stainless steel.

It can eliminate the work hardening and internal stress caused by deformation and prevent the possibility of stress corrosion. For welding parts, it can make the columnar crystal of welding seam change to equiaxial crystal, make the carbide on the weld heat-affected grain boundary dissolve in austenite, and prevent the possibility of intergranular corrosion and stress corrosion. For casting parts, it can avoid the production of a large number of high-temperature ferrite, to prevent the adverse impacts on the performance of austenitic stainless steel.

4. Pickling and passivation processing

Passivation of inner and outer walls of stainless steel pipes and fittings is also one of the key measures to prevent corrosion of stainless steel. Double compression pipe fittings

The anti-corrosion part of stainless steel is the thin layer of passivation film on its surface that does not react, which can be understood as an oxide film.

By passivation, iron scales or other defects embedded in the surface of the material can be removed to form a dense oxide layer. The existence of passivation film is the root cause of preventing corrosion of stainless steel.

Baodi company manufactures products in strict accordance with the quality assurance requirements of IS0 9001-2008, strictly controls every production link and produce earnestly to ensure that every product is 100% qualified, so as to satisfy and rest assured customers and maintain their fundamental interests.

Related Products

Mobile station

Add: No.888 Jiuhua Road, High-tech District, Nantong City, Jiangsu Province

Tel: +86-15371732888

Fax: +86-513-80677788

E-mail: jsbd@bdtube.cn

Copyright © 2020 Jiangsu Baodi Tube Co.,Ltd

+86-15371732888

+86-15371732888

Advisory

Advisory